How Cannabis-Infused Beverage Mixes Are Made

Almost any beverage can become an infused one with the addition of a futuristic beverage mix. Learn more and find out how these dissolvable cannabis powders are made.

Dissolvable Powders – It sounds like something from a science lab of the future: Stir a single-serving beverage mix powder into your favourite drink, and in less than a minute, it’s infused with THC or CBD. Welcome to the world of water-soluble cannabis, a highly innovative and relatively new format that can turn almost any beverage into a cannabinoid-infused drink.

While THC and CBD dissolve very well into fat-rich foods, such as chocolate and oils, they don’t play well with water. But traditional edibles made from those ingredients need time for the body to absorb the cannabinoids; the speed of their onset can vary widely.

Enter nano- emulsification — a process that turns cannabinoids into a liquid-friendly substance and improves their bioavailability. This means that they may be absorbed into the body relatively quickly.

L’et’s find out what goes into the innovative production process, from selecting the raw materials through to testing and packaging.

Picking Flower

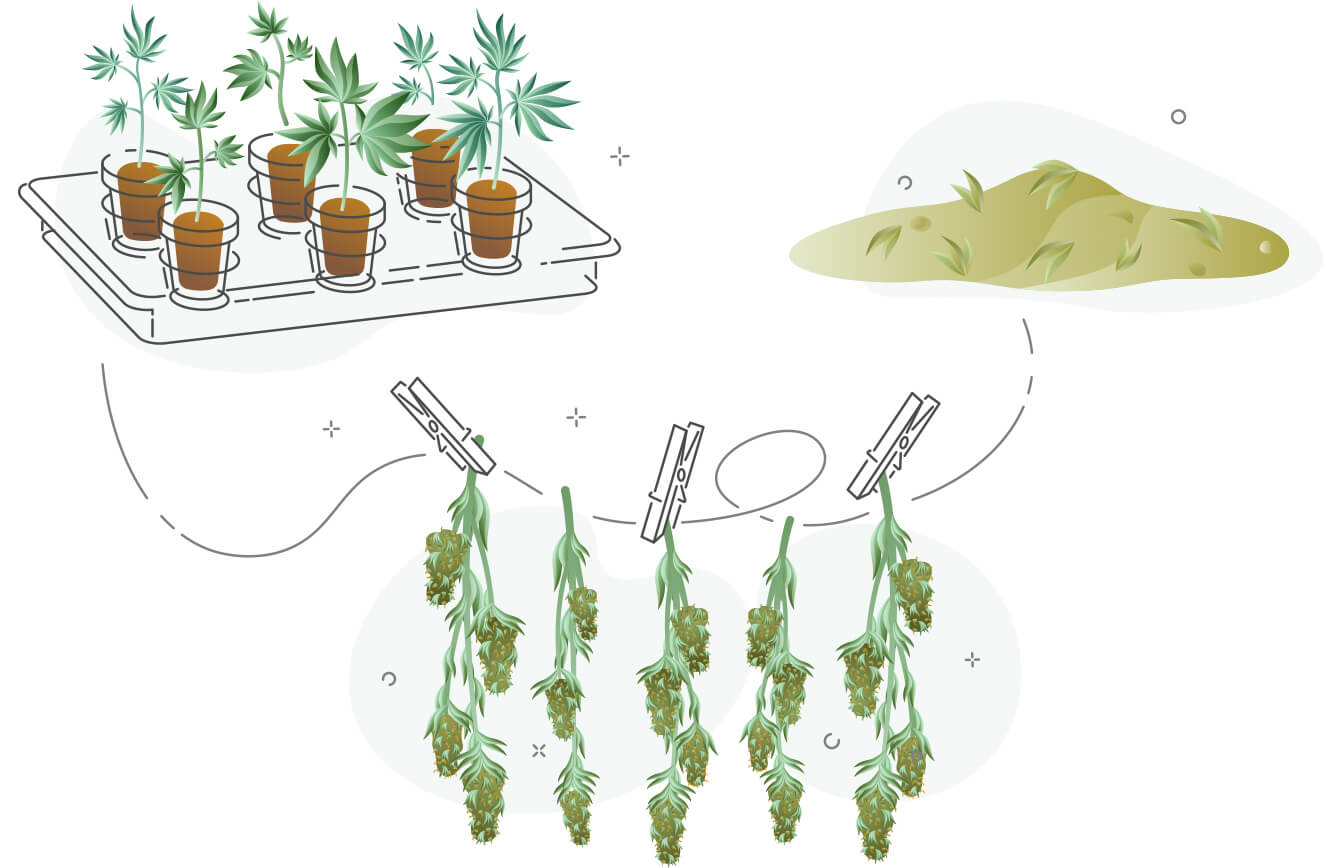

The first step in creating a cannabis infused beverage is producing the cannabis itself. Companies tend to use indoor-grown plants for its THC beverage mix and a blend of indoor and outdoor for the CBD variety, but there’s usually no specific strain involved — the distillation and formulation processes ensure the finished product is consistent, regardless of the plant genetics.

After harvesting, the cannabis flower is dried and cured in purpose-built drying rooms. The cannabis is then milled, a process that grinds the plant material into a medium or fine powder, and sent for extraction.

Fun Fact Edison can make 50 kilograms of RE:MIX beverage mix — equivalent to the weight of a baby hippo! — at one time

Creating the Extract

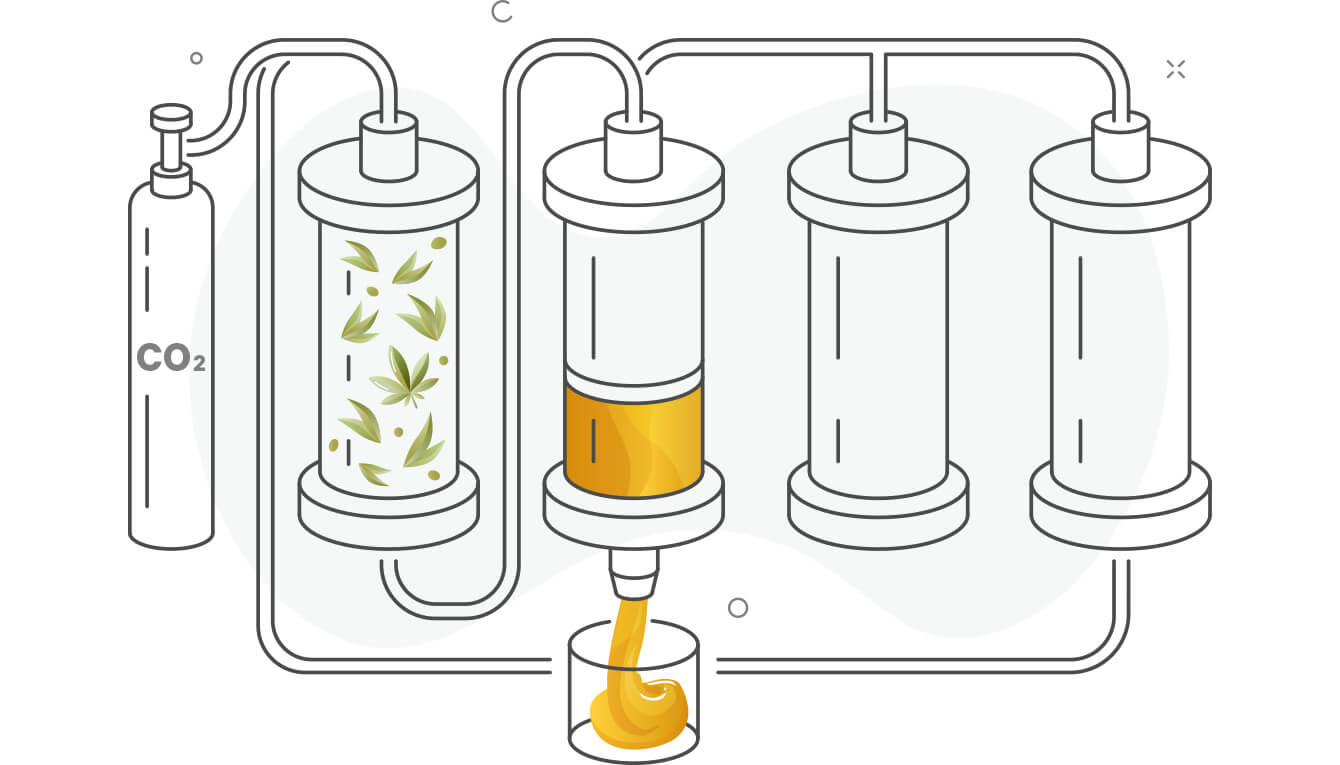

Here’s where the process starts to get technical: The milled cannabis is processed to isolate the essential cannabinoids (THC and/or CBD, depending on the particular product). The technique is similar to the way many other cannabis concentrates are made, where the cannabinoids are separated from the plant material to create a highly concentrated distillate.

To get specific, for a supercritical CO2 extraction method. The milled cannabis is fed into the extraction column, where carbon dioxide, or CO2, is exposed to high pressure and temperature. This causes the CO2 to become “supercritical” and act as a liquid and a gas at the same time, breaking the trichomes and dissolving the plant material. A careful adjustment of the temperature allows the targeted cannabinoids to attach to the CO2, and they’re collected as a concentrated extract.

Nano-Emulsification Time

Now the real science happens. Most use proprietary nano-emulsification processes. It’s helpful to remember that “nano” describes something extremely tiny, and “emulsification” means mixing two typically un-mixable liquids, like oil and water. The cannabis distillate must first be combined with a carrier oil; that mixture is then nano-emulsified, helping turn the cannabis distillate into water-friendly particles.

A quality check ensures the entire batch is mixed evenly — that is, that the cannabinoids are dispersed homogeneously throughout. Once the batch has passed these tests, the mixture is blanketed in nitrogen to reduce oxidisation and allowed to dry for three days. At this point, another round of quality-control testing occurs.

Testing Testing Testing Testing