How Cannabis Soft Chews are Made

A Flavourful Journey – Have you ever pondered the delightful mystery of how cannabis finds its way into those delicious soft chews? Step behind the scenes and explore the precise artistry involved in creating the perfect chewy delights.

While the rainbow of colours and an array of imaginative flavours may captivate your senses, the cannabis soft chews are more than just confectionery delights. Behind these tasty treats lies a world of meticulous manufacturing, rigorous testing, and culinary innovation. Join us as we unveil the process for crafting soft chews like Raspberry Vanilla (THC), Peach Mango (1:1), and Pineapple Orange (CBD).

Although each licensed producer boasts its own secret recipes — the fundamental process of making soft chews aligns with traditional candy-making methods, with the notable addition of cannabis.

Step 1: Mixing the Ingredients

Guided by a carefully crafted recipe, a symphony of sugar, water, and a thickening agent dances in specialised equipment, creating a watery solution with the perfect “brix” or sugar content. Some might offer a softer, cleaner bite with minimal stickiness, avoiding the typical gelatin. Intense fruity flavours, gleaned from customer preferences, are meticulously infused to minimise the cannabis taste. Distillate, chosen for easy blendability and near-flavourless properties, is then seamlessly incorporated.

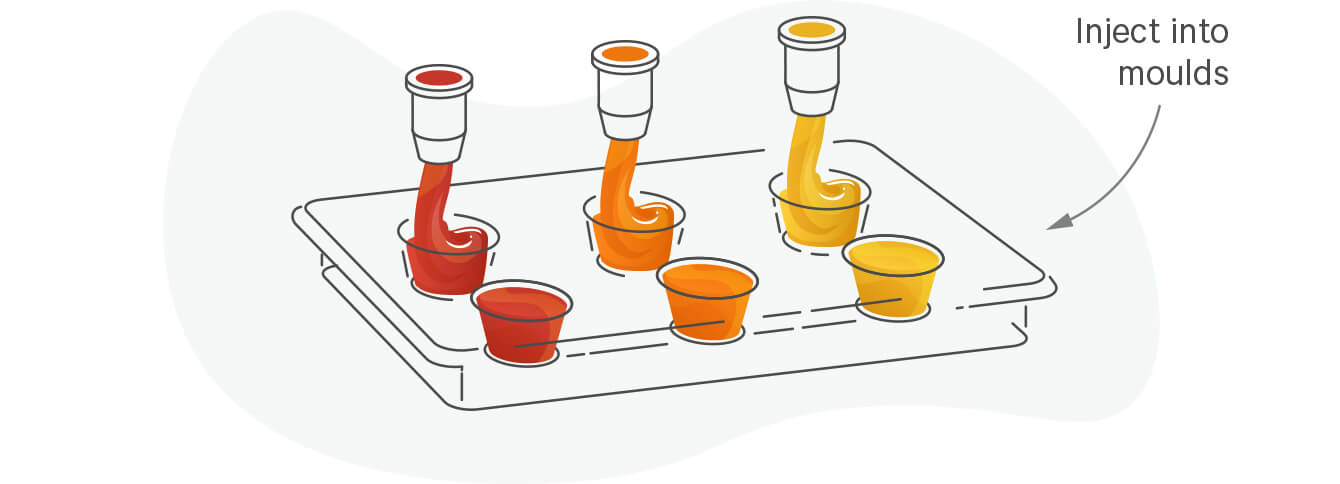

Step 2: Taking Shape

The liquid concoction takes form as it’s injected into moulds, left to cool, and solidify. Once set, the soft chews emerge, Some may go the extra mile by tumbling them in sugar for a sweet kick and to prevent sticking.

Step 3: Quality Testing

Beyond crafting, meticulous testing is crucial. Analytical chemists conduct in-house tests on each batch, deploying cutting-edge equipment to verify that THC and CBD content aligns with the labels as well as allowing them to sample products throughout production, ensuring a optimal end product.

Step 4: Packing and Shipping