How Ingestible Oils Are Made

You can stir them into a smoothie or blend them into cake batter. Get to know ingestible oils — what they are, how they’re made and ways to use them.

See How We Grow: Ingestible Oils

Belonging to the family of cannabis extracts, ingestible oils are made of concentrated cannabis compounds and can be consumed in many ways: mixed into food, stirred into drinks or ingested on their own. While some of these oils have a mild flavour and aroma, others are nearly tasteless and odourless; interestingly, this is one of the few cannabis formats where pungency isn’t always celebrated.

Curious about these versatile products and how they’re made? Here are the ins and outs.

Choosing the Right Cannabis

Just like making a perfume, the characteristics of an oil’s base ingredients will create certain qualities in the finished product.

The key is finding a cultivar with high cannabinoid content, or potency. The higher the cannabinoid content, the more efficient the CO2 extraction process will be.

There’s a long list of product specifications that that should be reviewed when sourcing, including:

Biomass type (whole flower, B grade or trim?) Cultivar (indica, sativa or hybrid?) Cannabinoid profile and concentrations Terpene profile Moisture content Age (when was it harvested?) Processing and storage conditions (how was it harvested, was it flash-frozen or dried and cured, and how was it packaged and stored?)

Isolating the Cannabinoids

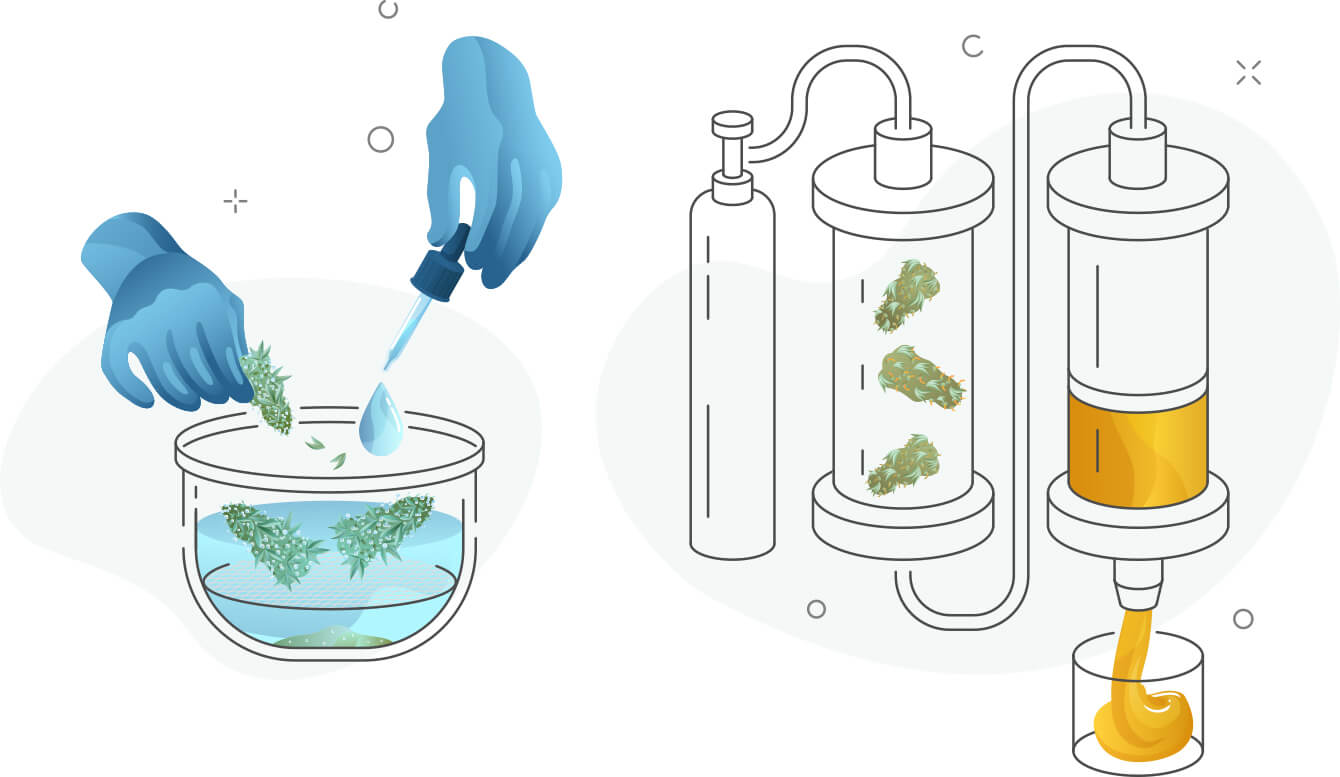

As with the creation of any type of cannabis extract, the dried flower must be processed to isolate the desired plant compounds — in the case of ingestible oils, that’s the cannabinoids THC and/or CBD. But not every product is created the same way.

CO2 extraction process, in which pressurised carbon dioxide is used to pull the elements out of the dried cannabis. The result is a full-spectrum oil that contains a large array of compounds, including cannabinoids, terpenes and flavonoids.

Distillate is another type of cannabis extract used to make ingestible oils, but it’s more refined than full-spectrum oil, devoid of nearly all its terpenes, unwanted cannabinoids and other compounds. Cold or cryogenic ethanol method can be used to first produce an extract: Simply put, the plants are soaked in alcohol, which absorbs all the desired compounds, and then the ethanol is removed. The ethanol extraction solvent is kept extremely cold to selectively extract cannabinoids, while leaving behind unwanted [compounds], such as chlorophyll and sugars.

The extract is further refined through distillation to remove any remaining aromas and to increase the purity of THC or CBD. For its CBD product, Distillation can also be used to refine the extract into ultra-pure crystals instead of an oil.

Mastering the blend

The cannabis distillate (oil or crystals) undergoes one final step to create a user-friendly product with good viscosity (the ability to flow smoothly).

Generally speaking, extracts are simply diluted with medium-chain triglyceride (MCT) oil, which is the fat found in foods like coconut. No extra ingredients are added to mask the natural taste and aroma of cannabis. as THC distillate has usually been refined to remove virtually all other cannabinoids and compounds found in the plant, it inherently has minimal cannabis flavour and scent. With a CO2 extraction process it can be used to create a full-spectrum extract, containing a few tasty, aromatic terpenes, such as caryophyllene, guaiol and bisabolol.

Because both ingredients in these products — the cannabis extract and the MCT oil — are oils, they remain mixed. But other patent-pending emulsion technology exist to suspend its oil in water. The process involves an emulsifier — a compound that has lipophilic (oil-loving) and hydrophilic (water-loving) sections that act as the interface between the oil and water layers. Mechanical shear is applied to the mixture to force the oil and water phases together to allow the emulsifier to stabilise the mixture, This coarse emulsion is then subjected to high-pressure homogenisation to further reduce the size of the cannabinoid-rich oil droplets and create a homogenous formulation.

Testing, testing All the ingestible oil – multiple in-house and/or third-party tests are made to ensure formulations are properly blended and have the desired cannabinoid potency, at both the extract and the finished product stages.

Before it’s sold through Authorised Retailers, ingestible oil is also tested for the presence of contaminants (such as pesticides, heavy metals, residual solvents, microbial and toxins). pH level tests can affect the efficacy of the preservation system, and its oil droplet size, which is important to predict the shelf life of the emulsion.

Droppers and stoppers

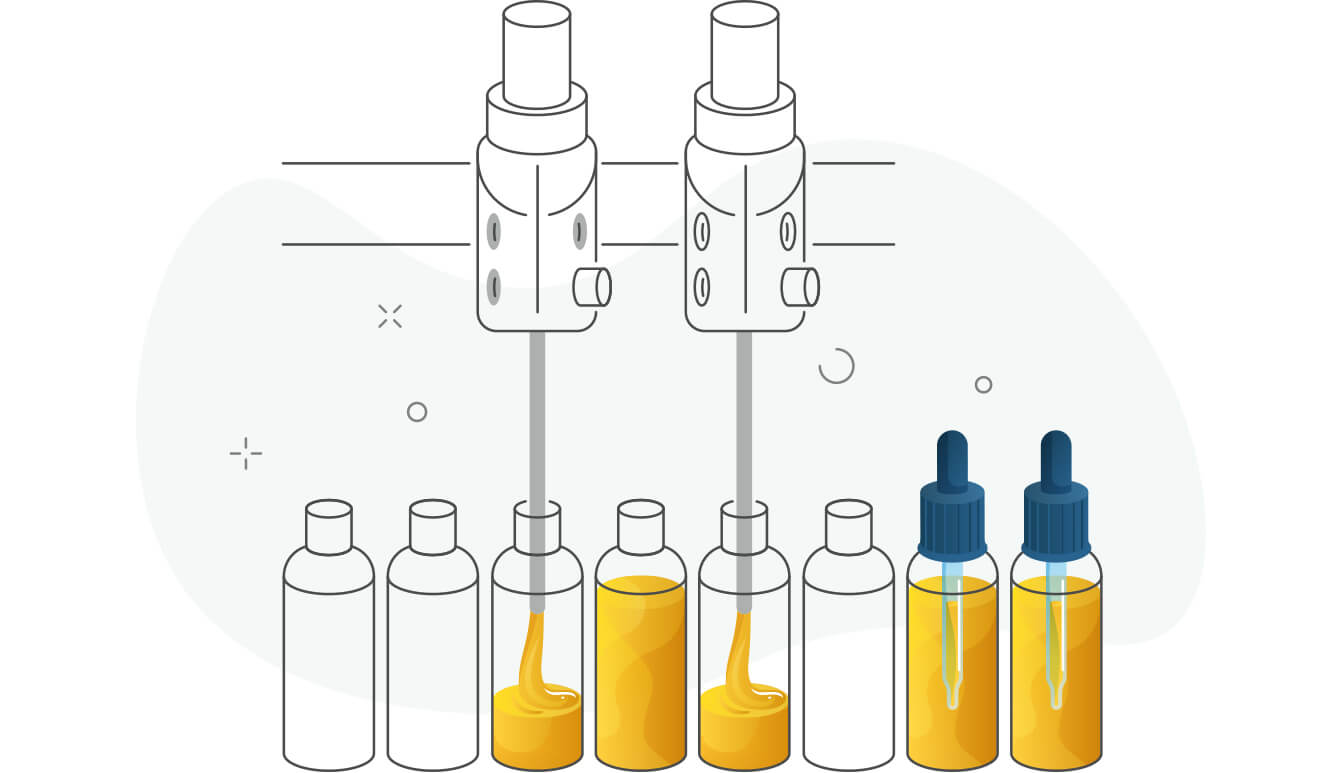

Consistency is a key benefit of legal cannabis. So how do ingestible oil Producers guarantee the same amount of THC and/or CBD each and every time? A completely homogenous formulation is key, followed by packaging designed for precise dispensing.

Syringes are for precision dosing – packaging may include an integrated syringe and stopper system that allows consumers to dispense X amount of mg of THC per gram of oil at a time. other Drops use a bottle (like those that essential oils come in) that dispenses a drop with a consistent concentration of CBD or THC when turned upside down and gently tapped.

Fat loves fat: Using the oils